I got the top plate from the laser cutter today. This is it after some wet sanding.

I got the plate cut at Smucker Laser Cutting & Metal Fabrication, located in Lancaster, PA.

I got the top plate from the laser cutter today. This is it after some wet sanding.

I got the plate cut at Smucker Laser Cutting & Metal Fabrication, located in Lancaster, PA.

Finally, some real progress:

The transistor idea didn't work, neither. I ended up just adding another output to the program.

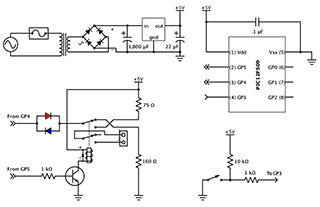

I got this on/off circuit set up on a breadboard today. The stupid voltage divider didn't work for the LEDs, so I have to try to use two transistors to control the LEDs. They are inside of the switch, by the way. I need to really start posting some pictures up here. Here is the new schematic. I haven't bought the transistors yet, but I am going to get some at RadioShack tomorrow. It should work, in theory.

Well, I got this PIC programmer, and with the help of this guy from the microchip forums named Dario Greggio I got the PIC to act as an on/off toggle with the off action requiring a button to be held down for a few seconds. I've since designed the PCB for the circuit. If anyone is interested in the circuit, PM me for more details. Getting a quantity of PCBs ordered would bring down the cost, greatly. I will draw and post up the schematic here later.

I got it all torn down days ago. I haven't decided if I am going to get another top plate laser cut or just modify this one. I want to go with a Bulgin switch, and not in the stock location. It's in a bad location where I have the amp sit I burn myself on the tube reaching for the switch to turn it off. I have a top plate designed in AutoCAD. I'm just waiting to hear from a place about laser cutting and if I need to add any considerations for beam width (maybe someone here could help me?). I drew everything literally the size I want it to wind up. The new tube sockets are smaller in diameter, so I ended up shrinking those holes in the drawing. I will still need a few more holes to mount a board that does the on/off latching and delays the signal to the headphones because I don't feel like putting the massive effort into pressing the latch to remove the headphones every time I turn it off, and I don't feel comfortable leaving them plugged in when I power it on.

The transformer end bell ended up ugly and rusty with all of the skin oils from handling. Oh well. That's getting powder coated and it was the plan from the get-go.

I got the capacitor brackets from Shapeways today.